About IMexI

Why IMexI

The Integrated Manufacturing excellence Initiative by Kaizen Hansei, in strategic association with Kaizen Institute, Sain and Patona Consulting, is designed to be a merit-driven initiative, with Operational Excellence aspirations of the industry participants in mind.

Today, with rapidly transformative and disruptive changes sweeping across value chains, it is necessary for one to be continually introspective of their readiness into the future. It can be credibly tested only by somebody who has spent sufficient field time in helping existing companies become lean and flexible…. and most importantly, inculcate a culture where transformation sustains.

It not only helps benchmark an existing state of excellence in a realistic way but also provides a seasoned advisory on what needs to be done for emulating the best in the industry.

THE IDEOLOGY

Manufacturing – Supply Chain Excellence is neither an accident and nor is it something that can happen spontaneously or without planning. It happens when visionary planning is complemented by meticulous and resolute implementation excellence and topped with adequate amounts of policy deployment based monitoring.

The program recognises Operational Excellence; no matter what the excellence philosophy. (could be TPM, TQM, Lean Sigma, WCM…or even a Home Grown, yet effective and sustained approach)

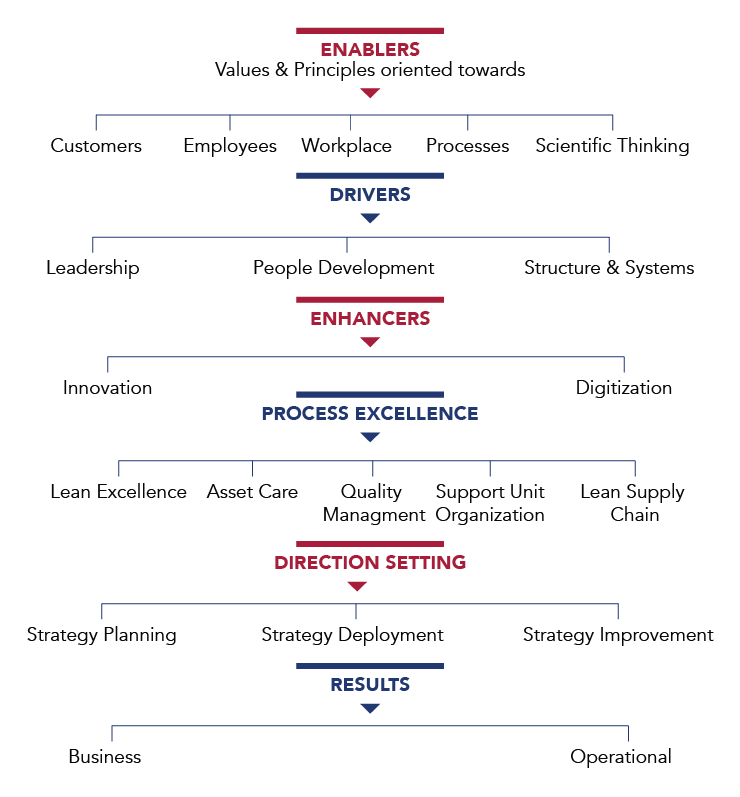

The On-site assessment methodology embodies this very principle, with a sound evaluation of the very foundations (The Enablers) that culturally makes up and differentiates various manufacturing organizations. It further goes on to evaluate the direction and effectiveness of deploying this into reality (by means of the Drivers involved as well as the Direction Setting Initiatives undertaken). Process Excellence initiatives are reviewed, so as to assess the Leanness and Flexibility of Operations, including the extended Supply chain. Having a roadmap, adoption of appropriate Technology (Automation/Smart/Predictive Analytics/Machine Learning/AI/IIOT, etc) and the ability to Innovate so as to derive competitive advantage is assessed to complete the site assessment.

THE IMexI ASSESSMENT FRAMEWORK *

IMexI Zone Canvas

Salient Benefits of Nominating Your Sites for IMexI

- This initiative will map your efforts on Operational Excellence and assign a particular maturity zone for the current state. It will further elaborate on where one is doing well and where one needs to improve to build a world-class organisation.

- 80% of operational excellence initiatives fail midway, either citing a lack of worker discipline or a loss of management focus. The assessment will identify and highlight their issues before they become threats. Hence, the advisories must be taken very seriously,

- A career move for manufacturing professionals in various organisations to learn from the experts as to what sustains operational excellence.

It is Hansei's responsibility to do everything necessary to reinforce the brand equity it represents. Hence, there will be no shortcuts and no laxity in deliverables/support to client organisations.

Salient Benefits of Applying to IMexI as a CORPORATE..

Designed for corporates with five or more manufacturing sites, IMexI Corporate moves beyond flagship-plant narratives to provide a statistically representative, system-level view of operational maturity.

In multi-site organisations, excellence is rarely uniform.

- Flagship plants often mask systemic gaps

- Performance varies widely across sites

- Boards and investors seek enterprise-level assurance—not anecdotes

Is excellence institutionalised across the enterprise—or isolated to a few locations?

What makes it special?

- IMexI is a premier program of facilitating operational excellence with a firm rooting in the contentious improvement ideology.

- It is for those seeking to implement an effective and sustainable Continuous Improvement program in their organisations.

- The assessments are conducted by professionals of repute and who have enormous experience in having transformed and initiated a culture of continuous improvement in supply chain organisations.

- Our value definition allows us to indulge in only those activities and initiatives that add

value and facilitates excellence in client organizations.

- Expect to validate your operational excellence program and projects

- Expect to identify additional projects which will expedite your journey along this path

- Expect to add value to your own teamwork, team spirit, and team-based learning

- Expect to gain out of the experience and wisdom of assessors, industry benchmarking and cross-industry learning… and much more

Who should consider applying?

- All serious disciples of lean and operational excellence.

- All organisations that want to have a quick reality check on the progress and maturity status of their efforts. (this could be an added advantage for organisations that are aspiring the attainment of other global recognitions as well as the ones which have achieved these recognitions in the past, but now want to test if the good practices have sustained themselves ever since).

- Those who want to make a positive statement towards stakeholder value enhancement

- Managements that want to understand the adequacy of and need for additional support by their supply chain organisations.

- Manufacturing organisations that will benefit from an outside-in perspective of whether they are doing sufficient enough.

- Organisations that believe in meritorious and credible recognitions. An accolade should be the natural outcome of an established process….and/but not the end in itself.

- A meritorious and fair based recognition will have a motivating effect on teams and internal initiatives… thus facilitating the cause of continuous improvement.

Qualifying Criteria

All passionate disciples of manufacturing and operational excellence are welcome to participate. They could be following any of the popular streams of excellence that exist today. (The assessment is agnostic to this aspect and treats all efforts equally, as long as they are in the right direction).

All interested applicants are encouraged to self-audit themselves, by requesting for the same from imexi@kaizenhansei.in. You may base your decision of participation on the outcome of the self-audit.

IMexI: A Six-Year Journey of Excellence and Growth (2020–2025)

Introduction

- Over the last five years, IMexI (Integrated Manufacturing Excellence Initiative) has established itself as a hallmark of operational excellence in the manufacturing industry.

- This Cerebral and Merit based assessment program has seen substantial growth in participation.

- This steady rise reflects an increasing commitment across industries to adopt best practices, innovation, and digital transformation.

Participation Reach

Diverse Industry Representation: Industries such as Chemical, Packaging, Electrical sectors, FMCG (Personal Care, Food, Nutraceuticals), Automotive (OEMs and Components), and Engineering Equipment emerged as dominant players.

A Catalyst for Future Growth

As IMexI progresses towards 2026, its focus on themes like Smart Manufacturing, Green Factories, and Digital Transformation will continue to inspire industries to embrace sustainability and innovation. The initiative’s journey from fostering foundational excellence to celebrating cutting-edge practices highlights its pivotal role in shaping the future of Indian manufacturing.

Besides the three above, based on feedback from Industry, IMexI 2026 will also see the introduction of the ADVANCED QUALITY EXCELLENCE MODULE and the ADVANCED SUPPLY CHAIN EXCELLENCE MODULE. This is for those companies that believe in MUCH beyond mere compliance.

Grand Total (Over 6 Years)

Breadth of Industry Participation